Binvent Series Cartridge Dust Collector

Product Details:

- Efficiency 85%-95%

- Scrubber Type Sponge

- Usage & Applications Industrial

- Material Stainless Steel

- Cooling System Air Cooling

- Warranty 5 Years

- Click to View more

Binvent Series Cartridge Dust Collector Price And Quantity

- 1 Unit

Binvent Series Cartridge Dust Collector Product Specifications

- Sponge

- Air Cooling

- Industrial

- 5 Years

- Stainless Steel

- 85%-95%

Binvent Series Cartridge Dust Collector Trade Information

- Cash in Advance (CID)

- 100 Unit Per Month

- 10 Days

- All India

Product Description

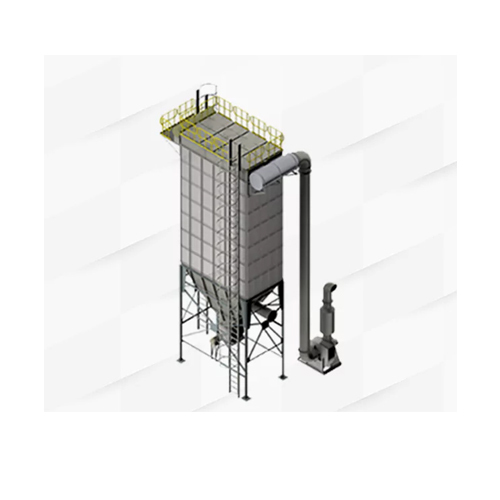

Binvent Series Cartridge Dust Collectors

The Binvent Series Cartridge Dust Collectors are advanced air filtration systems built for demanding industrial environments. Engineered to capture and contain airborne particulates, these collectors ensure a clean and safe workspace. The Binvent Series effectively handles a wide range of contaminants, including:

Dusts: Fine particulates, powdery substances, and hazardous dusts from various industrial processes.

Featuring a pulse-jet filter cleaning mechanism, the Binvent Series delivers reliable, high-performance dust management. This system uses short bursts of compressed air to dislodge dust from the cartridge filters, maintaining optimal airflow and filtration efficiency. Its an ideal solution for industries needing robust dust control with consistent operation.

Technical Specifications

| Model | 2-10 | 3-15 | 5-30 | 7-30 | 10-60 | 12-80 | 15-100 |

|---|---|---|---|---|---|---|---|

| Motor (kW) | 2.0 | 3.0 | 5.0 | 7.5 | 10.0 | 12.5 | 15.0 |

| Static Pressure (mmWG) | 125 | 150 | 200 | 275 | 250 | 250 | 250 |

| Air Flow Rate (CMH) | 1900 | 2000 | 3000 | 4000 | 6000 | 7500 | 8500 |

| Filtration Area (m) | 10 | 15 | 30 | 30 | 60 | 80 | 100 |

Key Features

- Durable steel construction for industrial durability

- Compact design suited for space-limited environments

- Easy filter access for quick maintenance

- Pulse-jet cleaning system requiring compressed air for efficient filter maintenance

- High-performance filtration for dust, fumes, and mists

- Customizable configurations for specific application needs

- Available in food-grade, anti-static, and flame-proof variants

- Optional explosion vent for hazardous dust environments

- Dust collection bin for straightforward disposal

- Energy-efficient motor options for long-term operation

Applications

- Pharmaceutical Processing: Controls dust from tablet compression, powder mixing, weighing, and packaging.

- Powder Handling: Manages dust during loading, mixing, bagging, weighing, sealing, and transferring in food, chemical, and pharmaceutical industries.

- Metalworking & Fabrication: Captures fine metal dust from cutting, grinding (belt, surface, swing), buffing, polishing, and drilling.

- Ceramics & Pottery: Extracts dust from material handling, forming, and grinding processes.

- Woodworking: Handles sawdust and particles in plywood manufacturing, paper slitting, sanding, and more.

- Cement & Building Materials: Controls dust in cement production, rubber processing, and construction material handling.

- Food & Beverage Processing: Manages dust in coffee, tea, sugar, spice grinding, packing, and handling.

- Bulk Material Handling: Reduces dust in conveyors, silos, crushers, and material dumping zones.

- Powder Processing Equipment: Contains particulates in shifter machines, ball mills, charging areas, and raw material handling.

- Packaging Lines: Extracts dust at weighing stations, pouch/bag packing machines, and final product handling.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Send Inquiry

Send Inquiry Send SMS

Send SMS